5TH:Ukugcinwa kwemoto kunye nenkqubo yesekethe

Imoto kunye nenkqubo yesekethe, engumthombo wamandla weumatshini wokunitha, kufuneka ihlolwe ngokungqongqo rhoqo ukunqanda ukophuka okungeyomfuneko. Ezi zilandelayo ngamanqaku aphambili omsebenzi:

1, Jonga umatshini ukuba awuvuzi

2, Jonga ukuba ifuse kunye nebrashi yekhabhoni yonakele (VS Motors kunye ne-inverter motors ngaphandle kwebrashi yekhabhoni)

3, Jonga iswitshi xa ingasebenzi kakuhle

4, Jonga i-wiring yokunxiba kunye nokuqhawulwa

5, Jonga i-motor, qhagamshela umgca, coca iibheringi (iibheringi) kwaye wongeze ioyile yokuthambisa.

6, Jonga iigiya ezifanelekileyo, ivili elihambelanayo kunye neepuli zebhanti kwinkqubo yokuqhuba, kwaye ujonge ingxolo engaqhelekanga, ukukhululeka okanye ukunxiba.

7, Yehlisa inkqubo: Jonga ubunzima beoyile yebhokisi yegiya kanye ngenyanga, kwaye wongeze ngompu weoyile.

Sebenzisa 2# MOBILUX igrisi yokuthambisa; okanye SHELL ALVANIL 2# igrisi yokuthambisa; okanye WYNN igrisi yokuthambisa yeenjongo ezininzi. Okanye ubhekisele kwi-“Manual Manual for Fabric Rolling down system”.

6TH:Uhlengahlengiso, ukurekhoda kunye negalelo lesantya

1, Isantya sokubaleka seumatshiniiseti, inkqaywe kwaye ilawulwa yi-inverter

2, Ukwenza useto, cofa u-A ukuqhubela phambili idijithi enye kunye no-V ukuhlehla idijithi enye,Cofa > ukuhambisa indawo enye ukuya ekunene.Emva kokuba useto lugqityiwe, cofa i-DATHA ukurekhoda, kwaye umatshini uya kuqhuba ngokwesantya somyalelo wakho.

3,Xa umatshiniiyasebenza, nceda ungacofa ngokungenamkhethe izitshixo ezahlukeneyo ze-inverter.

4, Ukusetyenziswa kunye nokugcinwa kwe-inverter, nceda ufunde "I-Inverter kunye ne-Manual Manual" ngokweenkcukacha.

7TH: Umbhobho weoyile

1, inkungu yohlobo lweoyile yemoto

A, Qhagamshela indawo yokuphuma yomoya yecompressor yomoya kwi-air inlet yesitofu esizenzekelayo ngetyhubhu yeplastiki, kwaye wongeze ioli yenaliti kwitanki yeoyile yemoto.

B, Lungisa icompressor yomoya kunye nonikezelo lweoyile, ubunzima beoyile kufuneka bube bukhulu xa umatshini usemtsha, ukuze ungangcolisi ilaphu.

C, Faka onke amacandelo ityhubhu yeoli ngokuqinileyo, kwaye xa uqala umatshini, unokubona ukuhamba kweoli kumbhobho, oko kukuthi, kuqhelekile.

D, Susa rhoqo ilindle kwisihluzo somoya.

2, ioyile yemoto ye-elektroniki

A, Umbane osebenzayo we-oyile yemoto ye-elektroniki yi-AC 220±20V, 50MHZ.

B,^ Khetha iqhosha lexesha kwaye ucinezele kube kanye ukunyusa isakhelo esinye.

C. >Iqhosha lokuhamba lomngxuma weoyile, cofa kube kanye ukuhambisa igridi enye, yahlulwe yangamaqela amane eABCD.

3, SET/RLW Ukuseta iqhosha lomsebenzi, cofa eli qhosha xa useta ngokutsha, kwaye ucinezele eli qhosha xa useto lugqityiwe.

4, Onke amaqhosha okuseta asetelwe ukucofa eli qhosha ngaxeshanye

5, isinqumli se-AU Cofa eli qhosha ukongeza ioyile ngokukhawuleza.

8TH:Isango lomatshini

1. Elinye lamasango amathathu e-umatshiniiyasuswa ukuze kuqengqeleke ilaphu, kwaye isango kufuneka libotshelelwe phambi kokuba kuqhutywe umatshini.

2, Isango elishukumayo lixhotyiswe ngesixhobo soluvo esimisa isango kwangoko xa livulwa.

9TH:Isixhobo sokujonga inaliti

1, Umtshina weNaliti uya kuxhuma ngokukhawuleza xa inaliti yokunitha iphuka, kwaye iya kuyithumela ngokukhawuleza kwinkqubo yokulawula, kwaye umatshini uya kuyeka ukubaleka ngaphakathi kwemizuzwana eyi-0.5.

2, Xa Inaliti yaphuka, isichongi seNaliti sikhupha ilitha lokukhanya.

3, Emva kokutshintsha inaliti entsha, nceda ucinezele isaphuli senaliti ukuyibuyisela kwakhona.

10TH:Isixhobo sokugcina umsonto

1, Isixhobo sokugcina umsonto sidlala indima entle ekondleni umsontoumatshini.

2, Xa umsonto othile ugqabhuka, ukukhanya okubomvu kwesixhobo sokugcina umsonto kuya kudanya kwaye umatshini uya kuyeka ukubaleka ngokukhawuleza kwimizuzwana eyi-0.5.

3, Kukho izixhobo zokugcina umsonto ezahlukeneyo nezingohlulwahlulwayo. Isixhobo esahlukileyo sokugcina umsonto sine-clutch, eqhutywa phezulu yipuli ephezulu kwaye ihle ngepuli esezantsi. Xa ubuyisela umva umsonto, nikela ingqalelo ukuba i-clutch ibandakanyeka.

4, Xa ilinti ifunyenwe ukuba iqokelele kwisixhobo sokugcina umsonto, kufuneka icocwe ngexesha.

11ST: Umqokeleli wothuli lweradar

I-1, Umbane osebenzayo womqokeleli wothuli we-radar yi-AC220V.

I-2, Umqokeleli wothuli we-radar uya kujikeleza kunye nomatshini kuwo onke amacala ukususa i-lint xa umatshini uqaliswa, kwaye uya kuyeka ukujikeleza xa umatshini uyeka.

3, Umqokeleli wothuli lweradar akayi kujikeleza xa iqhosha licofa.

4, Kubaqokeleli bothuli lweradar, ibhokisi ebuyela umva kumphezulu weshafti esembindini ixhotyiswe ngeebrashi zekhabhoni, kwaye uthuli olukwibhokisi ebuyela umva kufuneka lucocwe ngusombane rhoqo ngekota.

Isaziso:

Uxinzelelo lwebhanti kufuneka luhlengahlengiswe ngokufanelekileyo kububanzi bevili lokutya komsonto ngexesha ngalinye.

12TH:Ukujongwa kokuCoca

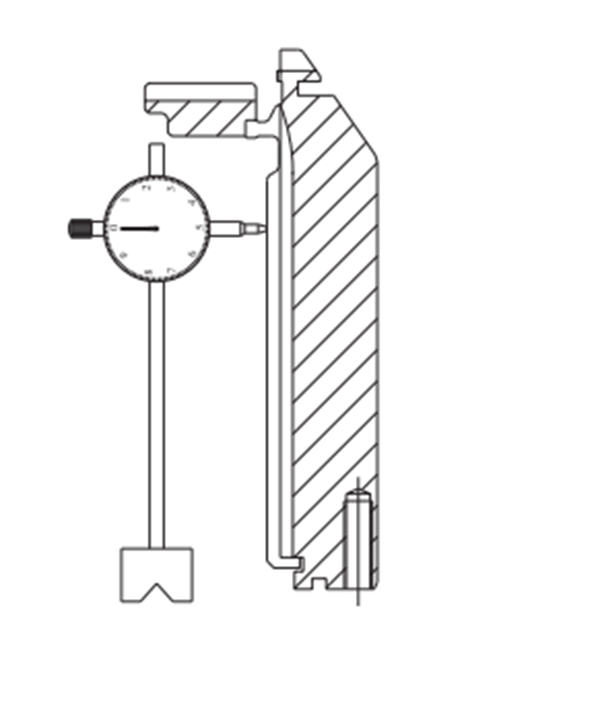

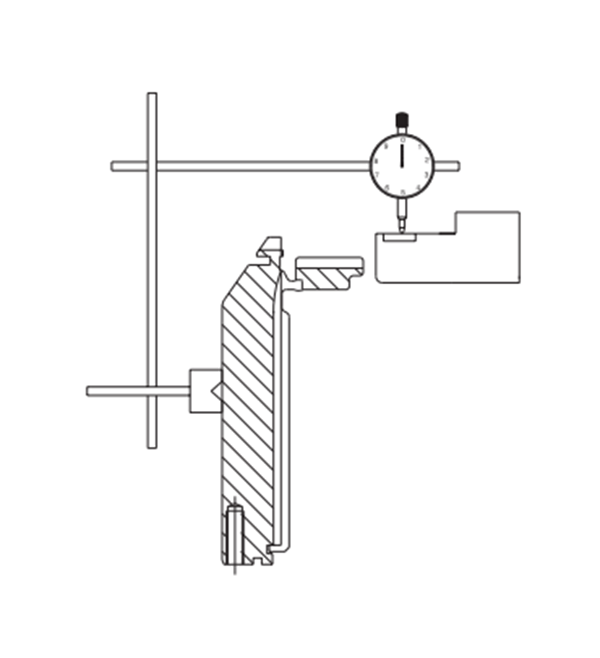

A, Sebenzisa igeyiji yokulinganisa ukujonga isithuba phakathi kwesilinda yenaliti kunye nonxantathu wesangqa esisezantsi. Uluhlu lwesikhewu luphakathi kwe-0.2mm-0.30mm.

B, Umsantsa phakathi kwe-cylinder yenaliti kunye nonxantathu wepleyiti ephezulu. Uluhlu lwesikhewu luphakathi kwe-0.2mm-0.30mm.

Ukutshintshwa kweesinki:

Ukuba i-sinker idinga ukutshintshwa, kukhethwa ukuguqula i-sinker ngesandla kwindawo ye-notch. Khulula izikrufu, susa ipleyiti esikiweyo, kwaye emva koko ubuyisele isinki esidala.

C, Ukutshintshwa kweenaliti:

Isikhundla phakathi kwe-latch yenaliti kunye ne-detector, indawo yomtshini kufuneka ibe kwindawo eqhelekileyo kunye nenaliti yokunitha inokudlula ngokucokisekileyo ngaphandle kokuyeka ngenxa yokuchukumisa umtshini.Ukukhethwa kwenaliti kunye nokufakwa kwayo kufuneka kulumke kakhulu, ukuguqula umatshini ngesandla kwindawo yomlomo, uze ususe inaliti ephosakeleyo ukusuka ezantsi kwaye uyibuyisele ngenaliti entsha.

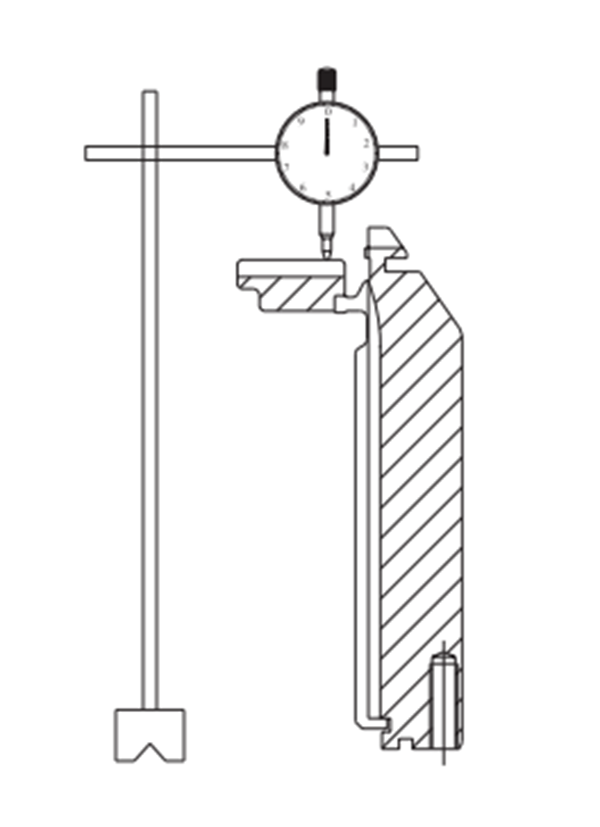

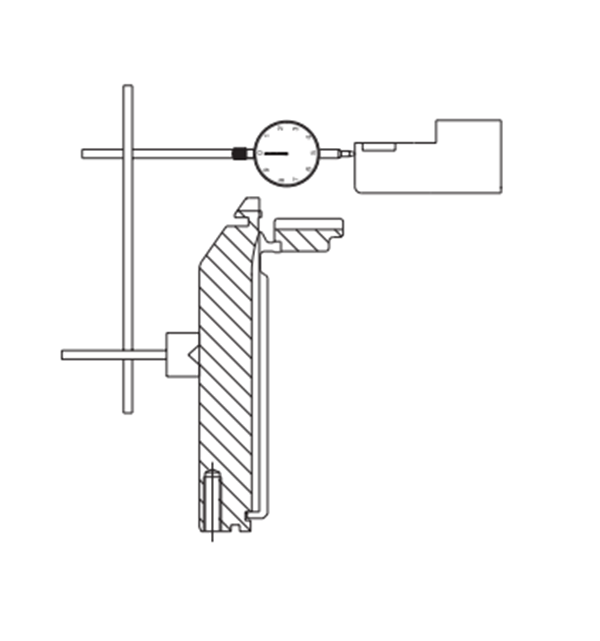

D, Uhlengahlengiso lwendawo yeradial ye-sinker

I-sinker kufuneka ilungiswe kwindawo ye-P, kwaye ke isalathisi sokudayela kufuneka silungiswe kwindawo ye-O.

Khulula isikrufu A ukutyhala indawo yeradial kanxantathu wediski ephezulu ngaphambili okanye ngasemva. Qwalasela indawo esime kuyo isinki ngegeyiji yokudayela.

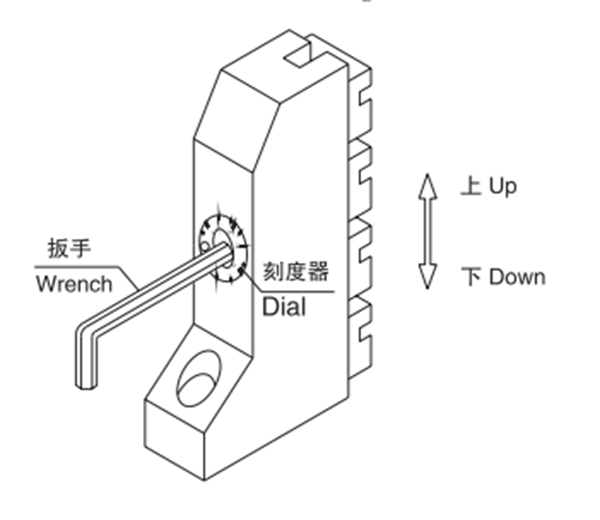

E, Uhlengahlengiso lobude benaliti

a, Sebenzisa i-6 mm Allen wrench ukulungisa isikali.

b, Xa i-wrench ijikeleza ngasekunene, ubude benaliti yokunitha buyancipha; xa ijika ngokuphambeneyo, ukuphakama kwenaliti yokunitha kuyenyuka.

13RD:Umgangatho wobuGcisa

Iimveliso zenkampani ziye zahlolwa ngokungqongqo, zahlengahlengiswa, kwaye zavavanywa. Umatshini oshushu ongenamthwalo awukho ngaphantsi kweeyure ezingama-48, kwaye ilaphu lepatheni yokuluka elinesantya esiphezulu alikho ngaphantsi kwe-8 yeekati. Ifayile yedatha yomatshini isekiwe, kwaye inokuveliswa ngokweemfuno zomsebenzisi.

1, i-cylinder concentricity (ukungqukuva)

umgangatho≤0.05mm

2, icylinder Parallelism

umgangatho≤0.05mm

3. Ukuhambelana kwepleyiti ephezulu

umgangatho≤0.05mm

5. I-coaxiality (umjikelezo) weplate ephezulu

umgangatho≤0.05mm

14TH:Indlela yokunitha

Oomatshini bokunitha abajikelezayoinokuhlelwa ngohlobo lwenaliti, inani leesilinda, ukucwangciswa kweesilinda kunye nokunyakaza kweenaliti.

Iumatshini wokunitha ojikelezayoubukhulu becala yenziwe yindlela yokutyisa umsonto, indlela yokuluka, indlela yokutsala kunye nendlela yokusasaza. Umsebenzi wendlela yokutyisa umsonto kukukhulula umsonto kwi-bobbin kwaye uthuthelwe kwindawo yokuluka, eyahlulahlulwe ibe ziindidi ezintathu: uhlobo olungalunganga, uhlobo oluhle kunye nohlobo lokugcina. Ukutyisa umsonto ongalunganga kukutsala umsonto kwi-bobbin ngokuxinezeleka kwaye uwuthumele kwindawo yokuluka elula ngesakhiwo kwaye ukufana kokutya komsonto akulunganga. Ukutyisa umsonto kukuhambisa umsonto kwindawo yokunitha ngesantya esingaguqukiyo somgca. Iingenelo kukutya okufanayo komsonto kunye nokuguquguquka okuncinci koxinzelelo, okunceda ekuphuculeni umgangatho wamalaphu ezinithiweyo. Uhlobo lokugcina umsonto wokutyisa kukukhulula intambo ukusuka ebhobhini ukuya kwibhobho yokugcina imisonto ngokujikeleziswa kwebhobhi yokugcina imisonto, kwaye umsonto utsalwa ngaphandle kwibhobho yokugcina umsonto ngokuxinana kwaye ungene kwindawo yokunitha. Kuba umsonto ugcinwe kwibhobhini yokugcina ixesha elifutshane lokuphumla, awukhutshiwe kwi-bobbin yokugcina i-diameter esisigxina, ngoko unokuphelisa ukuxinezeleka komsonto obangelwa ngumthamo we-larn ye-bobbin kunye neendawo ezahlukeneyo zokukhulula.

Umsebenzi wendlela yokunitha kukuluka umsonto kwilaphu lecylindrical ngomsebenzi womatshini wokunitha. Iyunithi yomatshini wokunitha onokuthi yenze ngokuzimeleyo umsonto owondliwe ube yiluphu ibizwa ngokuba yinkqubo yokunitha, eyaziwa ngokuba yi “Feeder”. Oomatshini bokunitha beSetyhula baxhotyiswe ngokubanzi ngeeFedi ezininzi.

Indlela yokunitha ibandakanya iinaliti zokunitha, izikhokelo zentambo, iisinki, iipleyiti zentsimbi ezicinezelayo, iisilinda kunye neecams, njl njl. Iinaliti zokunitha zibekwe kwiisilinda. Kukho iintlobo ezimbini ze-cylinder, i-rotary kunye ne-fixed. Kwilatshi yenaliti umatshini setyhula, xa cylinder ejikelezayo izisa inaliti latch kwi slot cylinder ukuya cam esisigxina, icam ityhala intunu yenaliti ukuhambisa inaliti latch kwaye uluke umsonto ibe loop. Le ndlela ilungele ukunyusa isantya sesithuthi kwaye isetyenziswa ngokubanzi. Xa i-cylinder ilungisiwe, inaliti ye-latch ityhalwa yikhamera ejikelezayo kwi-cylinder ukwenza i-loop. Le ndlela ilungele ukutshintsha indawo yekhamera ngexesha lokusebenza, kodwa isantya sesithuthi sincinci. Inaliti ijikeleza kunye ne-cylinder, kwaye i-sinker iqhuba intambo, ukuze umsonto kunye nenaliti zenze intshukumo ehambelanayo ukwenza i-loop.

15TH:Uhlengahlengiso lweDiskhi yeAluminiyam yokuTya umsonto

Uhlengahlengiso oluncinci: Xa ulungelelanisa i-diameter yevili lokutyisa umsonto, khulula i-nut yokuqinisa phezu kwediski ye-aluminium.

Qaphela ukuba xa isigqubuthelo esingaphezulu sijikeleza, kufuneka sigcinwe sithe tyaba kangangoko kunokwenzeka, kungenjalo ibhanti lezinyo liya kuwa liphuma kumjelo wevili lokutyisa umsonto.

Ukongeza, ngelixa uhlengahlengisa ububanzi bevili lokutyisa umsonto, ukunyanzeliswa kwebhanti lezinyo le-tension rack kufuneka kwakhona kuhlengahlengiswe. Ukulungiswa koxinzelelo lwebhanti.

Ukuba ukuqina kwebhanti lezinyo kukhululekile kakhulu, ivili lokutya umsonto kunye nebhanti lezinyo liya kutyibilika, ekugqibeleni likhokelela ekuqhawukeni komsonto kunye nenkunkuma yelaphu.

Lungisa ukutsalwa kwebhanti ngolu hlobo lulandelayo:

Amanyathelo okulungelelanisa: Khulula i-screw yokuqinisa ifreyimu yoxinzelelo, ulungelelanise indawo yevili lokuhambisa ukutshintsha ukunyanzeliswa kwebhanti yamazinyo.

Qaphela: Ngalo lonke ixesha i-diameter yevili lomsonto utshintshwa, ukuqina kwebhanti lamazinyo kufuneka kuhlengahlengiswe ngokufanelekileyo.

16TH:Ilaphu lokuthatha phantsi inkqubo

Umsebenzi welaphu lokuthotywa kwelaphu kukusebenzisa iirola ezijikelezayo ezijikelezayo ukucinezela ilaphu elingwevu, ukuzoba ilaphu elisandula ukubunjwa ukusuka kwindawo yokwenza iluphu, kwaye ulijijelwe kuhlobo oluthile lwephakheji. Ngokwemowudi yokujikeleza yerola yokutsala, indlela yokuthatha ilaphu yohlulwe yazintlobo ezimbini: uhlobo oluphakathi kunye nohlobo oluqhubekayo. Ukolula okungapheliyo kwahlulwe ku-Positive stretching kunye ne-Negative stretching. I-roller yokutsala ijikeleza kwi-angle ethile ngamaxesha aqhelekileyo. Ukuba isixa sokujikeleza asinanto yakwenza noxinzelelo lwelaphu elingwevu, libizwa ngokuba li-Positive stretching, ngelixa ukuba ubungakanani bokujikeleza buthintelwe kukuxinana kwelaphu elingwevu, kubizwa ngokuba yi-Negative stretching. Kwindlela yokutsala eqhubekayo, i-roller yokutsala ijikeleza ngesantya esiqhubekayo, ngoko ke iphinda itsalwe kakuhle.

Kwezinyeumatshini wokunitha ojikelezayo, kufakwe indlela yokukhetha inaliti yokuluka uyilo kunye nombutho wombala. Ulwazi lwepateni eyiliweyo lugcinwa kwisixhobo esithile, kwaye iinaliti zokunitha zifakwa emsebenzini ngokwenkqubo ethile ngokusebenzisa indlela yothumelo.

Imveliso yethiyori yomatshini wokunitha wesetyhula ikakhulu ixhomekeke kwizinto ezifana nesantya, igeyiji, idayamitha, i-feeder, iiparamitha zesakhiwo selaphu kunye nokucoleka komsonto, okunokubonakaliswa yimveliso yesiphumo = isantya secylinder (rev / amanqaku) × isilinda ububanzi (cm/2.54) × inani le feeder. Umatshini wokunitha ojikelezayo unokuguquguquka ngakumbi ekusetyenzweni kwemisonto, kwaye unokuluka iindidi ezininzi zoyilo kunye nemibala, kwaye unokuluka amaqhekeza esambatho esinye esigqityiweyo. Umatshini unesakhiwo esilula, kulula ukusebenza, unemveliso ephezulu, kwaye uhlala kwindawo encinci. Ithatha inxalenye enkulu kumatshini wokunitha kwaye isetyenziswa ngokubanzi kwimveliso yangaphakathi kunye nempahla yangaphandle. Nangona kunjalo, inani leenaliti zokusebenza kwi-cylinder alinakunyuswa okanye lincitshiswe ukutshintsha ububanzi belaphu elimpunga, ukusetyenziswa kokusika kwe-cylindrical grey cloth kukhulu.

Ixesha lokuposa: Oct-23-2023