Inkqubo yeMveliso

Inkqubo yemveliso yeOomatshini bokunitha belaphu leTerrylulandelelwano oluntsonkothileyo lwamanyathelo enzelwe ukuvelisa amalaphu eterry akumgangatho ophezulu. Ezi zindwangu zibonakaliswe ngezakhiwo zazo eziziintambo, ezibonelela nge-absorbency egqwesileyo kunye nokuthungwa. Nalu ujongo oluneenkcukacha kwinkqubo yemveliso:

1. Ukulungiselela izinto eziphathekayo :

Ukukhetha imisonto : Khetha imisonto ekumgangatho ophezulu elungele ukwenziwa kwelaphu leterry. Ukhetho oluqhelekileyo lubandakanya umqhaphu, ipolyester, kunye nezinye iifiber zokwenziwa.

Ukutya ngomsonto : Layisha umsonto kwi-creel system, uqinisekise ukuxinana okufanelekileyo kunye nokulungelelaniswa kokuthintela ukuqhawuka kunye nokuqinisekisa ukondla okungaguqukiyo.

2. Ukuseta oomatshini :

Uqwalaselo lwenaliti : Misela iinaliti ngokwegeyiji yelaphu efunwayo kunye nepateni. Oomatshini bokunitha beTerry ngokuqhelekileyo basebenzisa iinaliti zokuluka.

Ukulungiswa kwe-Cylinder : Lungisa i-cylinder kwi-diameter echanekileyo kwaye uqinisekise ukuba ihambelana ngokufanelekileyo nendandatho ye-sinker kunye neenkqubo zekhamera.

ICam System Calibration : Ukulungelelanisa iinkqubo zekhamera ukulawula ukuhamba kweenaliti kunye nokufezekisa iphethini yokuthunga efunwayo.

3. Inkqubo yokunitha :

Ukutya ngomsonto : Umsonto utyiswa kumatshini ngokusebenzisa izixhasi zentambo, ezilawulwayo ukugcina ukuxinezeleka okungaguqukiyo.

I-Needle Operation : Njengoko i-cylinder ijikeleza, iinaliti zenza i-loops kwintambo, idala i-cloth. Iisinki zincedisa ekubambeni nasekukhululeni iilophu.

Ukuqulunqwa kweLoop : Iisinki ezikhethekileyo okanye iinaliti ze-crochet zandisa i-arc ye-sinker ye-loop yarn ukwenza i-loops.

4. Ulawulo loMgangatho :

Ukubeka iliso ngexesha lokwenyani : Oomatshini bale mihla baxhotyiswe ngeenkqubo zokubeka iliso eziphambili ezilandelela ukuxinana kwelaphu, ukuqina, ukuguda, kunye nobukhulu ngexesha lokwenyani.

Uhlengahlengiso oluzenzekelayo : Umatshini unokulungelelanisa ngokuzenzekelayo iiparamitha ukugcina umgangatho welaphu ongaguqukiyo.

5. Emva kokulungiswa :

I-Fabric Take-down : Ilaphu elinithiweyo liyaqokelelwa kwaye lifakwe kwi-batch roller. Inkqubo yokwehlisa iqinisekisa ukuba ilaphu linenxeba ngokulinganayo.

Ukuhlola kunye nokuPakisha : Ilaphu eligqityiweyo lihlolwe iziphene kwaye emva koko lipakishwe ukuze lithunyelwe.

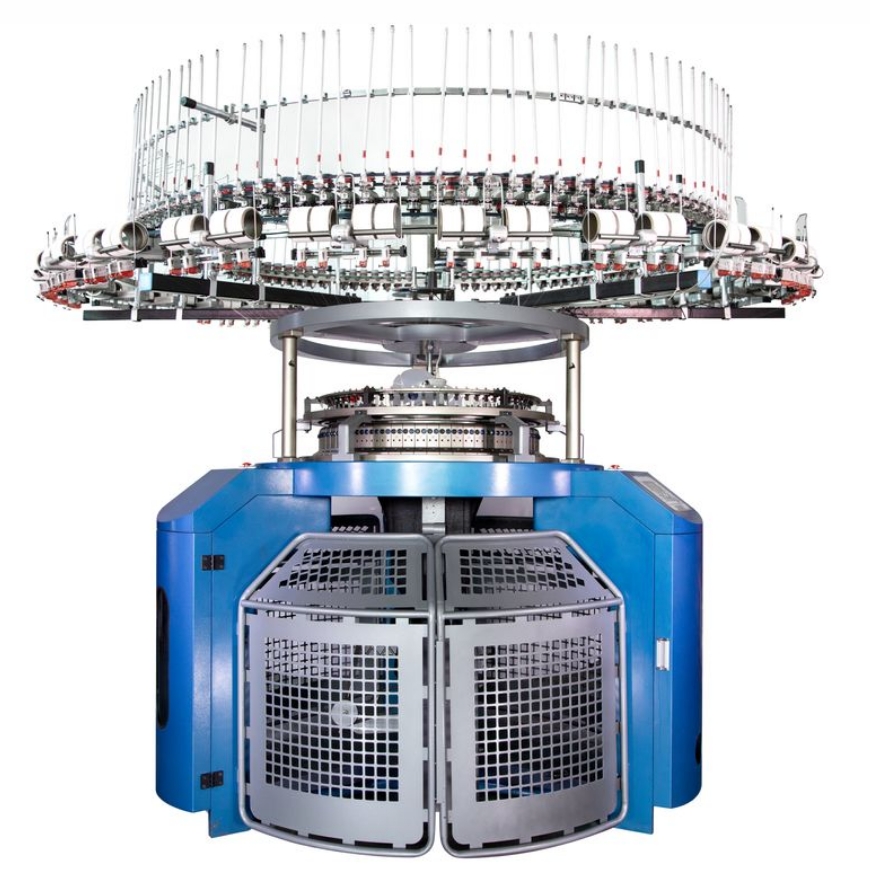

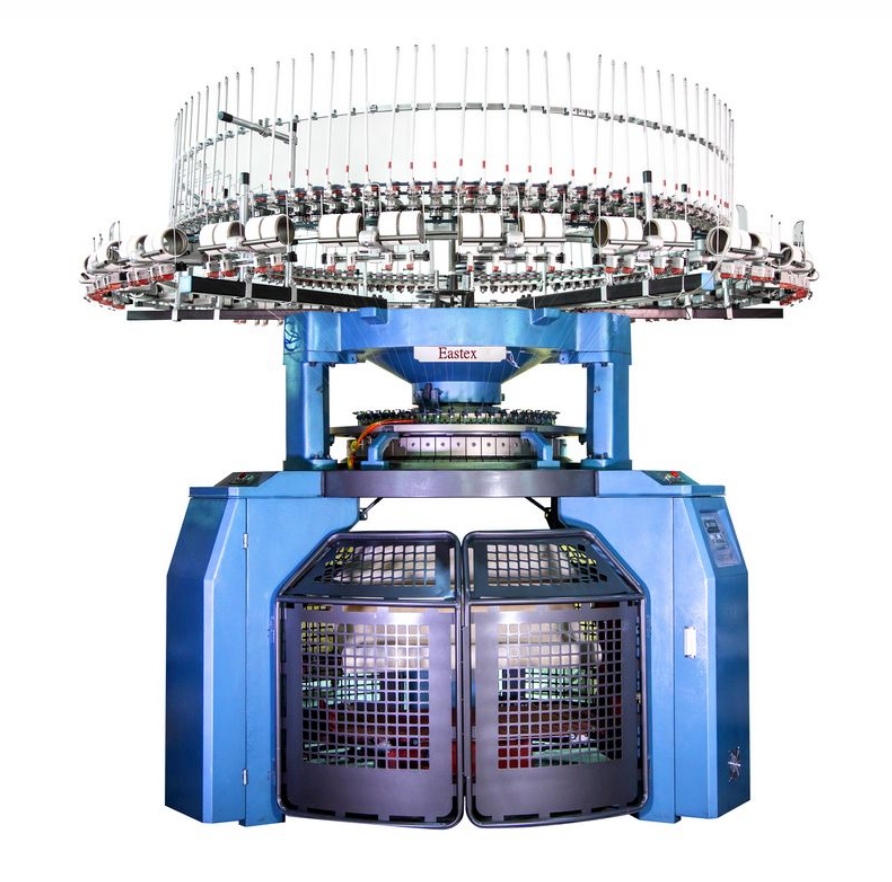

Amacandelo kunye nemisebenzi yawo

1. Ibhedi yenaliti :

Isilinda kunye nokuDayela : I-cylinder ibamba isiqingatha esisezantsi seenaliti, ngelixa i-dial ibamba isiqingatha esiphezulu.

Iinaliti : Iinaliti zeelatshi ziqhele ukusetyenziselwa isenzo sazo esilula kunye nokukwazi ukucubungula iintlobo ezahlukeneyo zemisonto.

2. IiFidi zoMsonto:

Ubonelelo ngoMsonto : Ezi zixhasi zibonelela ngomsonto kwiinaliti. Ziyilelwe ukusebenza ngeentambo ezahlukeneyo, ukusuka kwicoci ukuya kubukhulu.

3. Inkqubo yeCam :

Ukulawulwa kwePatheni yokuthunga : Inkqubo yekhamera ilawula ukuhamba kweenaliti kwaye imisela ipateni yokuthunga.

4. Inkqubo yeSinker:

I-Loop Holding : I-sinkers ibamba i-loops kwindawo njengoko iinaliti zihamba zinyuka kwaye ziphantsi, zisebenza ngokubambisana kunye neenaliti ukwenza iphethini yokuthunga efunwayo.

5. I-Fabric Take-up Roller :

I-Fabric Collection : Le roller idonsa ilaphu eligqityiweyo kude nebhedi yenaliti kwaye ivuthelwe kwi-roller okanye i-spindle.

Uqwalaselo

Oomatshini bokunitha belaphu leTerryIza ngolungelelwaniso olwahlukeneyo ukuhlangabezana neemfuno ezahlukeneyo zemveliso. Ulungelelwaniso oluphambili lubandakanya:

-Ibhedi yenaliti enye Uhlobo lwe-Multi-cam:Olu hlobo lusetyenziswa ngokubanzi ngenxa yokuguquguquka kunye nokukwazi ukuvelisa ubude obuhlukeneyo be-loop.

- Inaliti ephindwe kabini ibhedi yeSetyhula eWeft Machine: Lo mzekelo usebenzisa iibhedi ezimbini zeenaliti ukwenza iilophu zobude obahlukeneyo.

Ukufakela kunye nokuKhomishini

1. Umiselo lokuqala :

Ukubekwa komatshini : Qinisekisa ukuba umatshini ubekwe kwindawo ezinzileyo kunye nenqanaba.

Amandla kunye neSibonelelo soMsonto : Qhagamshela umatshini kumthombo wamandla kwaye usete inkqubo yokubonelela ngentambo.

2. Ulungelelwaniso :

Ulungelelwaniso lwenaliti kunye neSinker : Lungisa iinaliti kunye neesinki ukuqinisekisa ukulungelelaniswa okufanelekileyo.

Uxinzelelo loMsonto : Lungiselela izixhasi zomsonto ukugcina uxinzelelo olungaguqukiyo.

3. ImiSebenzi yoVavanyo :

Isampulu yeMveliso : Qhuba umatshini ngemisonto yovavanyo ukuvelisa amalaphu esampuli. Jonga iisampulu ukuhambelana komthungo kunye nomgangatho welaphu.

Uhlengahlengiso : Yenza naluphi na uhlengahlengiso oluyimfuneko ngokusekelwe kwiziphumo zovavanyo ukuqinisekisa ukusebenza kakuhle.

ULondolozo kunye neNkonzo yasemva koThengiso

1. ULondolozo lwarhoqo :

Ukucocwa kwemihla ngemihla : Coca umphezulu womatshini kunye nentambo yomsonto ukususa inkunkuma kunye nemicu.

Uhlolo lweVeki : Jonga izixhobo zokutyisa umsonto kwaye ubuyisele naziphi na iindawo ezigugileyo.

Ukucoca Ngenyanga : Coca ngokucokisekileyo i-dial kunye ne-cylinder, kuquka iinaliti kunye neesinki.

2. Inkxaso yobuGcisa :

Inkxaso ye-24/7 : Abaninzi abavelisi banikezela ngenkxaso yobugcisa be-clock-clock ukuncedisa nayiphi na imiba.

Iwaranti kunye noLungiso : Ukugubungela iwaranti ebanzi kunye neenkonzo zokulungisa ngokukhawuleza ziyafumaneka ukuze kuncitshiswe ixesha lokuphumla.

3. Uqeqesho :

Uqeqesho lwabaSebenzisi : Uqeqesho olubanzi lwabaqhubi ekusebenzeni komatshini, ukugcinwa, kunye nokulungisa iingxaki zihlala zinikezelwa.

4. UQinisekiso loMgangatho :

Uhlolo lokugqibela : Umatshini ngamnye uhlolwa okokugqibela, ukucocwa, kunye nokupakishwa ngaphambi kokuthunyelwa.

Ukumakishwa kwe-CE : Oomatshini bahlala bephawulwa nge-CE ukuqinisekisa ukuba bahlangabezana nemigangatho ephezulu yokhuseleko kunye nokusebenza.

Ukuqukumbela

Oomatshini bokunitha belaphu leTerryzizixhobo eziyimfuneko kushishino olulukiweyo, ezikwaziyo ukuvelisa amalaphu eterry akumgangatho ophezulu kwizicelo ezahlukeneyo. Inkqubo yokuvelisa ibandakanya ukulungiswa kwezinto ngononophelo, ukuseta umatshini ngokuchanekileyo, ukunitha okuqhubekayo, ulawulo lomgangatho, kunye nokulungiswa emva kokulungiswa. Aba matshini baguquguquka kakhulu kwaye bafumana ukusetyenziswa kwimpahla, amalaphu asekhaya, kunye namalaphu obugcisa. Ngokuqonda inkqubo yemveliso, amacandelo, uqwalaselo, ufakelo, ukugcinwa, kunye nenkonzo emva kokuthengisa, abavelisi banokwandisa imisebenzi yabo kwaye bahlangabezane neemfuno ezahlukeneyo zemarike yelaphu.

Ixesha lokuposa: Apr-15-2025